Compact-designed supercapacitors using free-standing single-walled carbon nanotube films

Date:10-01-2012 Print

As energy storage devices, supercapacitors, also known as electrochemical capacitors, have attracted much attention because of their high power and energy densities and long cycle life. Supercapacitors can be applied to many fields such as electric vehicles, pulse power applications and portable devices. With the development of electronic devices, such as notebooks, mobile phones, however, the existing configuration and performance of supercapacitor devices cannot provide the peak power without becoming too heavy or bulky to meet the demand of increasing functionality of electronic devices. Therefore, the developments of supercapacitor devices are directed towards thin, light, cheap solutions.

Single-walled carbon nanotubes (SWCNTs) are the attractive candidate for high performance electrode material of supercapacitors because of their high conductivity, low mass density and large specific surface area in combination with the unique mechanical properties. Conventionally, SWCNT-based electrodes have been achieved by mixing SWCNTs with conductive binders and coating collector electrodes with this composite or directly depositing SWCNTs onto substrates. However, the addition of binders degrades the properties of SWCNT electrodes, and the substrates used for SWCNT electrodes are not flexible and tough enough. As a result, the reported supercapacitors based on SWCNT electrodes are stacked design in general.

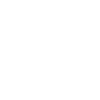

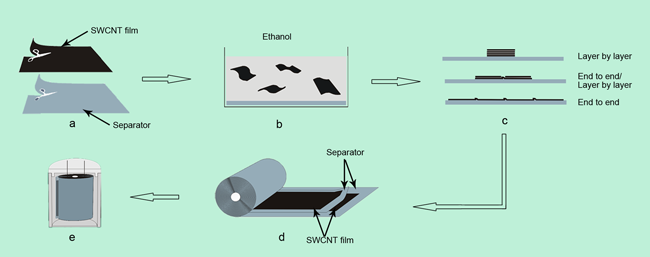

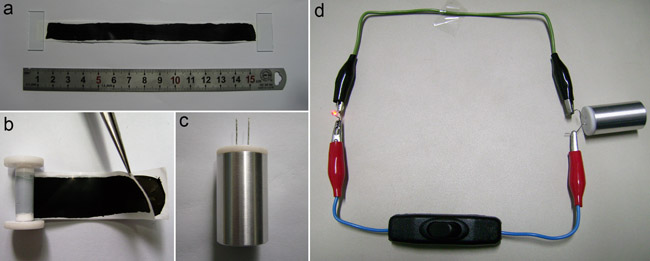

Recently, the group “Nanometer Materials and Mesoscopic Physics” at the Institute of Physics, Chinese Academy of Sciences and Beijing National Laboratory for Condensed Matter Physics, successfully realized the assembly of compact-designed supercapacitors using large-scaled free-standing and flexible single-walled carbon nanotube (SWCNT) films as both anode and cathode. Prof. Weiya Zhou, Dr. Zhiqiang Niu, Prof. Sishen Xie et al., cooperating with Dr. Jun Chen from University of Wollongong, Australia, and Prof. Hong Li, Dr. Guoxing Feng, from IOP CAS, developed a prototype of the processing procedures to obtain the uniformly spreading of the directly grown SWCNT films onto the separators serving as both electrodes and charge collectors without metallic current collectors, leading to a simplified and lightweight architecture. The area of SWCNT film on a separator can be scaled up and its thickness can be extended. High energy and power densities (43.7 Wh/kg and 197.3 kW/kg, respectively) were achieved for the fabricated SWCNT film-based compact-designed supercapacitors with small equivalent series resistance. The specific capacitance is about 35 F/g. These results clearly show the potential application of free-standing SWCNT film in compact-designed supercapacitor with enhanced performance and significantly improved energy and power densities.

Over the past a few years, this group has been engaged in studies on preparation, properties and potential applications of SWCNT film and published several important papers, e.g. Nano. Lett. 2007, 7, 2307; Adv. Mater. 2009, 21, 603; Nano. Lett. 2009, 9, 2855. This work is a continuation of their ongoing efforts and has been published recently in Energy & Environmental Science (2011, 4, 1440).

This work was supported by Chinese Academy of Sciences, the National Natural Science Foundation of China, and the Ministry of Science and Technology of China.

Article Linkage:Compact-designed supercapacitors using free-standing single-walled carbon nanotube films.pdf

|

| Fig. 1 Schematic diagram of assembling compact-designed supercapacitor using free-standing flexible SWCNT films. |

|

| Fig. 2 Optical images of (a) the SWCNT films spread out on a separator, (b) rolled design of the separator with SWNCT films and (c) the resulting compact-designed supercapacitor. (d) Optical image of the resulting compact-designed supercapacitor used to glow a red light-emitting diode. |

|

| Fig. 3 (a) Typical CVs of a representative compact-designed SWCNT film supercapacitor at different scan rates. (b) The specific capacitance of the SWCNT film supercapacotor as a function of the scan rate. (c) Typical galvanostatic charge/discharge curves of the compact-designed SWCNT film supercapacitor. (d) The Nyquist impedance plots of the compact-designed SWCNT film supercapacitor with frequency ranging from 10 kHz to 0.1 Hz. |