Tensile Plasticity in Metallic Glasses with Pronounced second Relaxations

Date:08-02-2012 Print

Metallic glasses are commonly brittle, as they generally fail catastrophically under uniaxial tension. The demonstration of plastic flow in tension i.e. true ductility, is long a holy grail for metallic glasses.

Recently, Wei Hua WANG’s group,Institute of Physics, Chinese Academy of Sciences,reports that pronounced macroscopic tensile plasticity achieved in a new La-based metallic glass which possesses exceptional strong second relaxations and nanoscale heterogeneous structures. It demonstrates that the second relaxation is closely correlated with the activation of the structural units of plastic deformation and global plasticity, and the activation of second relaxations at the temperature and time scale within the stress-strain experiment is a necessary condition for the metallic glass to circumvent brittleness and show tensile plasticity. The results have implications for understanding the mechanisms of plastic deformation and structural origin of the second relaxations of glassy materials. It also provides useful physical insight into the origins of tensile plasticity which may point the way forward to the development of new materials and for solving the brittleness in metallic glasses.

[Reference]

Tensile Plasticity in Metallic Glasses with Pronounced β-Relaxations (Phys. Rev. Lett.108 015504 (2012))

Recently, Wei Hua WANG’s group,Institute of Physics, Chinese Academy of Sciences,reports that pronounced macroscopic tensile plasticity achieved in a new La-based metallic glass which possesses exceptional strong second relaxations and nanoscale heterogeneous structures. It demonstrates that the second relaxation is closely correlated with the activation of the structural units of plastic deformation and global plasticity, and the activation of second relaxations at the temperature and time scale within the stress-strain experiment is a necessary condition for the metallic glass to circumvent brittleness and show tensile plasticity. The results have implications for understanding the mechanisms of plastic deformation and structural origin of the second relaxations of glassy materials. It also provides useful physical insight into the origins of tensile plasticity which may point the way forward to the development of new materials and for solving the brittleness in metallic glasses.

[Reference]

Tensile Plasticity in Metallic Glasses with Pronounced β-Relaxations (Phys. Rev. Lett.108 015504 (2012))

|

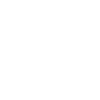

| Fig.1. (a) The deformation mode map summarizing the tension tests at different temperature and strain rates, the filled squares denote for the brittle fracture while filled circles for the ductile fracture, the DBT is represented by half-filled squares. (b) The temperature and strain rate dependent of the temperature of DBT and fitted with Arrhenius relation. (c) The photograph of the La-MG before and after tension with stain 30% (at 353 K and 1×10-5s-1). (d) The SEM image of a ductile fracture surface of the La-MG (at 333K and 1×10-5s-1and total strain 6%), and the arrow indicates the shear bands. (image by Wei Hua WANG et al.) |

|

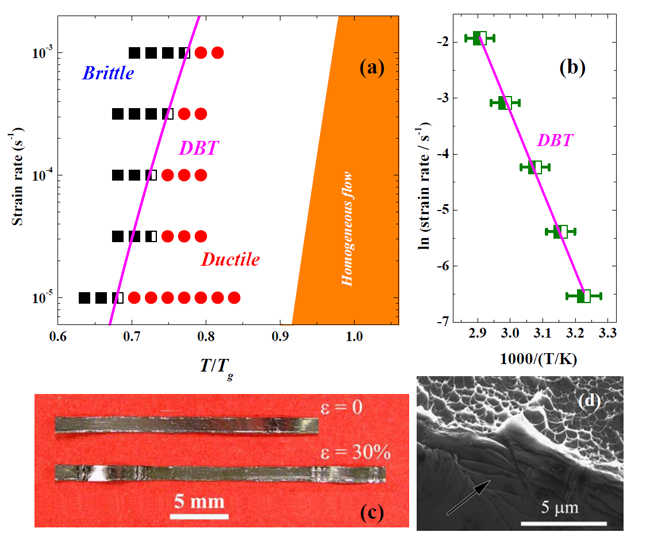

| Fig.2. Comparison of the behavior of β relaxations between the La-based MG with other ten typical MGs. Temperature dependent E” of the La-MG showing distinct relaxations peaks, indicating high density potential shear transformation zones in the metallic glasses. (image by Wei Hua WANG et al.) |