Clarify the flow in metallic glass

Date:11-10-2014 Print

Metallic glasses are commonly brittle, as they generally fail catastrophically under high stress. In this paper, we report a method which can realize remarkable homogeneous plastic deformation at room temperature for various metallic glasses, and the method can be applied to precisely study deformations of metallic glasses. We find that any metallic glass can be made ductile or brittle through the control of the features of flow units, and the deformation of a metallic glass depends on the activation energy, time and density of flow units which can be determined by our method. The found microstructural information has potential benefits including better understanding of the deformation mechanisms and provides a strategy in solving the brittleness in metallic glasses and design of glasses with improved performance in applications.

|

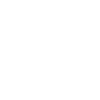

| Figure 1. A schematic illustration of the helical mandrel winding and (b) the clockwork spring winding methods. (c) An image of the released La75Ni7.5Al16Co1.5 ribbon after helically winding and holding in place for 24 h. (d) A picture of the released ribbon after 40 d, showing no significant residual strain recovery. (e) A SEM picture of the surface topography of the coiled MG showing no shear bands. |

|

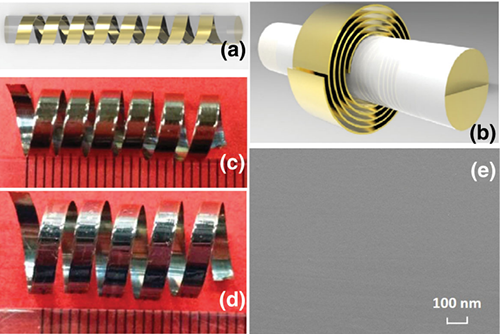

| Figure 2: From left to right, the released Ce70Al10Ni10Cu10, Ce68Al20Cu10Co2, La75Ni7.5Al16Co1.5, La68Al20Cu10Co2, La60Al20Co20, and (b) Pd40Ni10Cu30P20 ribbons, which were mandrel wound and held for 24 h. (c) The residual strainεvs the activation energy of flow units (the solid line is a guide for the eye) for these ribbons. |

|

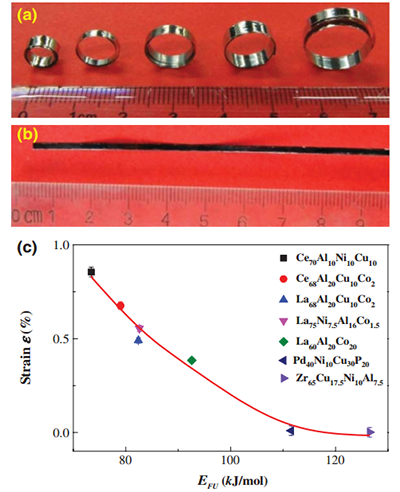

| Figure 3. (a) The intensity ofβrelaxations of La75Ni7.5Al16Co1.5 gradually reduces with an increase of annealing time. (b) The relationship between ε, annealing time, and the intensity of relaxation (normalized by theβ-relaxation peak height of as-cast ribbon). The inset is the picture of coiled MGs which were annealed (from left to right) for 0, 15, and 30 min before imposing mandrel winding, respectively. |

|

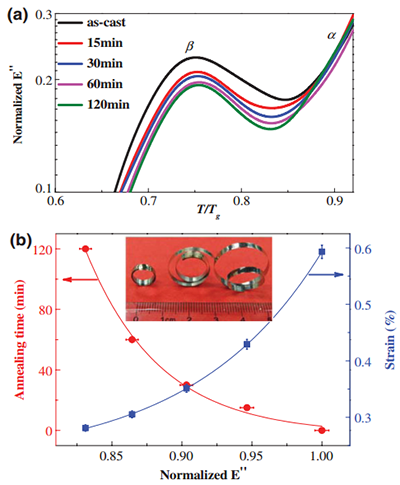

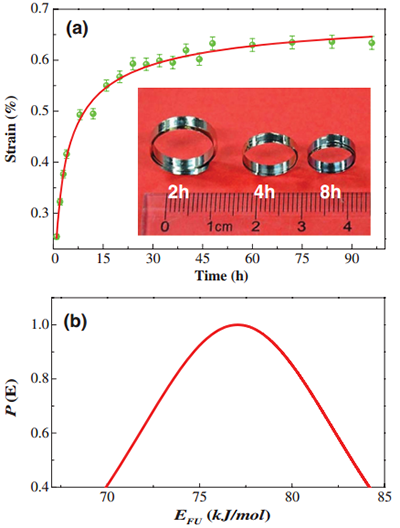

| Figure 4. (a) The change in ε of La75Ni7.5Al16Co1.5 MG which was wound and held for different time spans. The inset shows an image of ribbons which were wound and then held in place for 2, 4 and 8 h, which have different curvature radii. The red curve is the fit usingε(t)=ε0/(1+c). (b) The activation energy spectrum of the MG. |