High-performance and compact-designed flexible thermoelectric modules enabled by a reticulate carbon nanotube architecture

Date:26-06-2017 Print

Thermoelectric (TE) modules composed of p-type and n-type TE materials can directly convert thermal energy generated from natural heat sources or ubiquitous waste heat to valuable electric energy. The novel flexible TE materials, such as carbon nanotube (CNT) macrostructures, conducting polymers, and CNT/polymer composites, have attract considerable attention due to their unique advantages and extensive application prospects.

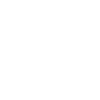

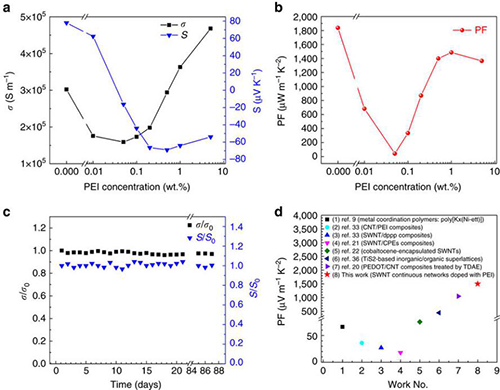

Nowadays, the thermoelectric power factor (PF) of flexible p-type TE material has been improved to ~2000 μW m-1 K-2 at room temperature, which could compete with the state-of-the-art inorganic TE materials. However, high-performance and air-stable flexible n-type TE materials are still deficient, which impedes the performance optimization of flexible TE modules. The single-walled carbon nanotube (SWNT) films synthesized directly via a floating catalyst chemical vapor deposition method have distinctive reticulate architecture and superior electrical properties. Recently Dr. ZHOU Wenbin and Dr. FAN Qingxia as well as Dr. ZHANG Qiang in Prof. ZHOU Weiya and Prof. XIE Sishen’s group from Institute of Physics, Chinese Academy of Sciences, have developed an excellent flexible n-type film based on the SWNT films.

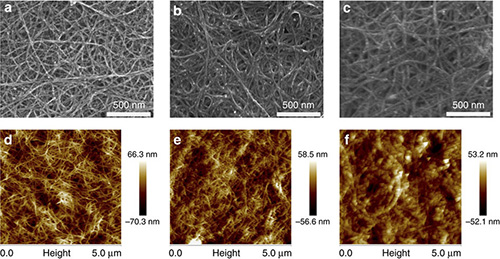

The researchers found that the pristine p-type SWNT films can be rapidly and conveniently switched to n-type films by drop-casting the solution of polyethyleneimine in ethanol. The n-type films exhibit a high thermoelectric PF of ~1500 μW m-1 K-2 and an outstanding long-term stability in air without encapsulation. Moreover, they design and successfully fabricate a compact and efficient flexible TE module based on the large-area continuously synthesized CNT films and by a localized doping technique.

Compared with the conventional π-type TE module, the compact-designed module obviates the need for gold or silver top electrodes deposited on each TE legs and metal interconnects between n-type and p-type legs, and avoids the influence of the contact resistance as well as is easily large-scale produced. Based on the outstanding host materials and novel-configuration, the performance of the module is markedly superior to that of previously reported flexible TE modules.

The light-weight and flexible p- and n-type thermoelectric films and novel-configuration modules based on carbon nanotube continuous networks in this study exhibit attractive application potentials in portable and flexible thermoelectric conversion as well as novel sensing applications. The research results also open opportunities for the industrial production of flexible TE modules.

This study entitled “High-performance and compact-designed flexible thermoelectric modules enabled by a reticulate carbon nanotube architecture” was published on Nature Communications, 8, 14886 (2017).

The study was supported by the National Science Foundation (Grand Nos. 11634014, 51172271, 51372269 and 51472264), the Ministry of Science and Technology of China (Grand No. 2012CB932302), the Chinese Academy of Sciences (Grand No. XDA09040202).

|

| Fig.1 Thermoelectric properties and stability of the pristine and doped SWNT films. (Image by Institute of Physics) |

|

| Fig.2 Morphology characterization of the pristine and doped SWNT films. (Image by Institute of Physics) |

|

| Fig.3 Preparation and demonstration of compact-designed TE module. (Image by Institute of Physics) |

Contact:

Institute of Physics

ZHOU Weiya

Email:wyzhou@iphy.ac.cn

Key word:

Flexible thermoelectric, carbon nanotube, N-type, compact-designed;

Abstract:

Thermoelectric modules can generate electricity directly from heat and have applications to waste heat energy conversion and sensing. Here researchers have designed and fabricated a compact flexible thermoelectric module based on an air-stable n-type single-walled carbon nanotube reticulation, which can reach a high power factor of 1500 μWm-1K-2.