Metallic Glass Skin: New Flexible Strain Srnsor Driving E-skin’s Practical Applications

Date:12-10-2017 Print

The pace to pursuit electronic skin (e-skin) has never stopped from scientific fiction to new kinds of multifunctional e-skins, since they have broad applications in intelligent robots, biomimetic prosthetics,health monitoring, and many other areas. However, current strain sensing materials are of deficiencies for practical applications, such as poor electrical conductivity, large energy consumption, complex manufacturing process and high cost. Therefore, exploration of new strain sensitive materials for e-skin is of crucial significance.

Metals and alloys are one of the oldest and most widely used materials but suffer from small elastic limit (<0.5%), which makes them uncompetitive when being used to e-skin. Metallic glasses which are alloys of disordered atomic packing shows ten times larger elastic limit than conventional alloys. Based on metallic glasses, Haijie Xian from the Institute of Physics, Chineses Academy of Sciences, under the guidance of Prof. Wei-hua Wang, Prof. Haiyang Bai, Prof. Yanhui Liu has developed a new flexible strain sensor which was named “Metallic glass skin”.

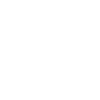

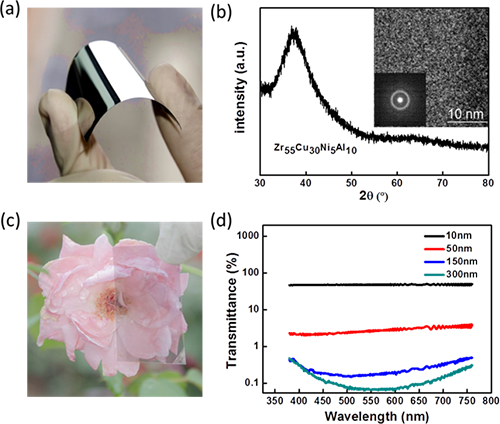

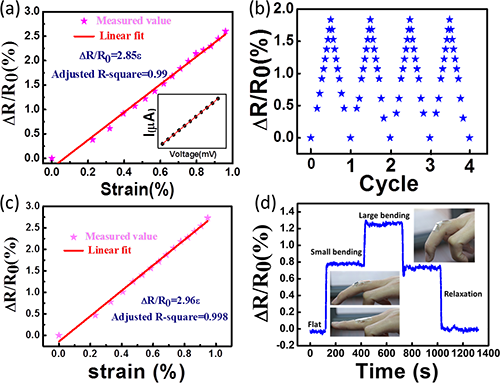

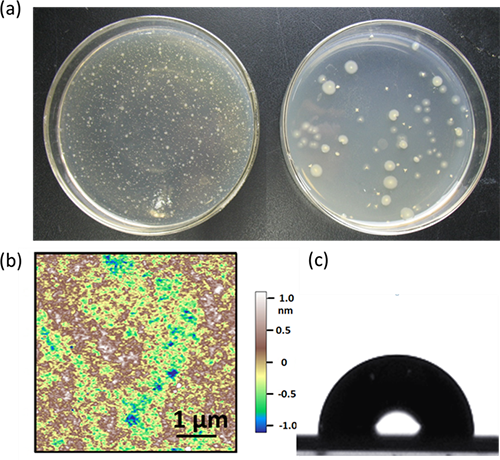

Metallic glass skin, synthesized by depositing metallic glass thin film Zr55Cu30Ni5Al10 on flexible substrate polycarbonate, exhibits piezoresistance effect with a gauge factor around 2.86, large detectable strain range (~1% or 180 degree bending angle, ideal elastic limit is 4.2% in room temperarure),good conductivity (>5000S cm-1),and extremely low temperature coefficient of resistance (9.04×10-6 K-1). In addition, the metallic glass skin shows distinct antibacterial behavior, excellent reproducibility and repeatability (over 1000 times), nearly perfect linearity, low manufacturing cost, and negligible energy consumption. The combination of these features is essential for e-skin’s practical applications. Besides demonstrating a candidate material for e-skin, this work also provides unprecedent perspective on functional use of metallic glasses by combining its superb electrical, mechanical and thermal properties together.

This study, published in Applied Physics Letters (111, 121906, 2017), was supported by the National Science Foundation, MOST 973 Program of China and the Key Research Program of Frontier Sciences, the Chinese Academy of Sciences.

|

| FIG. 1. (a) The image of the MG skin. (b) GIXRD and HRTEM confirm its glassy nature. (c) “Transparent” MG skin. (d) Transmittance spectra of MGTF with different thicknesses. |

|

| FIG.2. Piezoresistance effect measurements of the MG thin films. (a)Relative change of resistance vs. strain. Electrical resistance changes during the cycling test (b) and 1000 times later (c). (d) Diagram illustrating MG skin used to monitor movements of hands at different bending degrees |

|

| Fig.3. (a) Gauge factor shows almost no change with aging time. (b) The dependence of relative changes of the electric resistance on temperature of the MG skin. (c) The dependence of sensitivity on deposition rate and thickness of the sample. (d) Thermal stability of some conventional materials used for e-skin and MG skin. |

|

| Fig.4. Antibacterial behavior of MG skin. |

Contact:

Institute of Physics

Wang Weihua

Email:whw@iphy.ac.cn

Key word:

metallic glass skin, piezoresistance effect, flexible strain sensors, good electrical conductivity , thermal stability

Abstract:

Searching strain sensitive materials for electronic skin is of crucial significance because of the restrictions of current materials such as poor electrical conductivity, large energy consumption, complex manufacturing process and high cost. Here, we report a flexible strain sensor based on Zr55Cu30Ni5Al10 metallic glass thin film which we name as metallic glass skin. The metallic glass skin, synthesized by ion beam deposition, exhibits piezoresistance effect with a gauge factor around 2.86, large detectable strain range (~1% or 180° bending angle), and good conductivity. Compared with other e-skin materials, the temperature coefficient of resistance of the metallic glass skin is extremely low (9.04×10-6 K-1) , which is essential for reduction of thermal drift. In addition, the metallic glass skin exhibits distinct antibacterial behavior desired for medical applications, and also excellent reproducibility and repeatability (over 1000 times), nearly perfect linearity, low manufacturing cost, and negligible energy consumption, all of which are required for electronic skin for practical applications.