Meniscus-modulated blade coating enables high-efficient perovskite minimodules

Date:11-07-2024 Print

In the past decade, perovskite solar cells (PSCs) have made significant progress, becoming a promising class of photovoltaic devices for commercialization. Achieving large-area, high-efficiency perovskite modules is key to their commercialization. To date, small-area PSCs based on α-FAPbI3 have achieved a certified efficiency of 26.1%. However, the efficiency of corresponding perovskite modules is still low, mainly due to poor quality of large-area perovskite films.

Meniscus coating methods, including blade and slot-die coating, are favored for their simplicity, cost-effectiveness and high throughput, which is ideal for scaling up perovskite films. However, these methods are strongly influenced by precursor solution viscosity and concentration, solvent boiling points and vapor pressures, and specific process parameters. The interaction among these factors significantly impacts perovskite crystallization growth, and their effective regulation is crucial for large-scale, high-quality perovskite films. Recently, Huang Chunjie, Tan Shan and Yu Bingcheng in Prof. Meng qingbo and Prof. Li Dongmei’s group from Institute of Physics, Chinese Academy of Sciences, have developed a meniscus-modulated blade coating method combined with a high-concentration precursor solution to upscale high-quality perovskite films, and fabricated small-area cells (0.09cm2) with notable 25.31% efficiency and 12.4cm2 FAPbI3 minimodules with certified 23.1% efficiency.

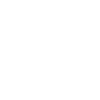

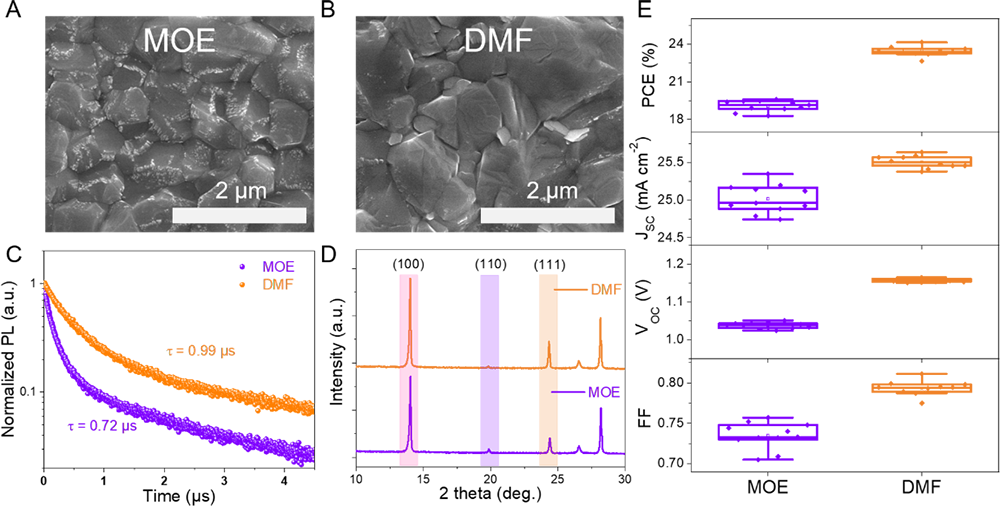

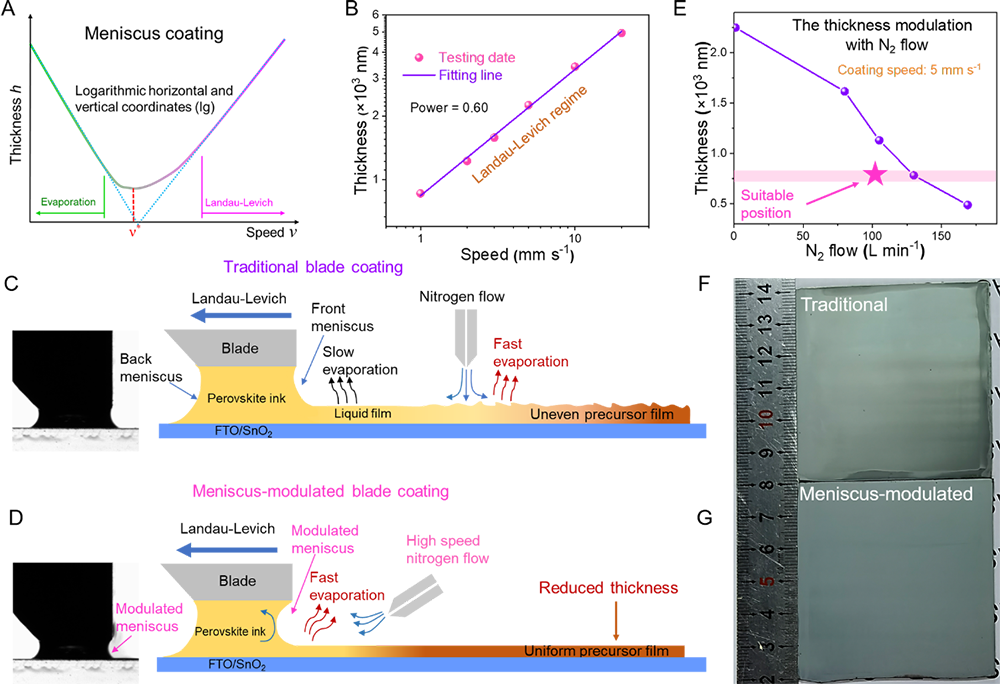

Researchers compared coordination interactions of low-boiling-point, high-saturated-vapor-pressure solvents (such as MOE) and high-boiling-point, low-saturated-vapor-pressure solvents (such as DMF) for precursor solutions. These solvents are more challenging to evaporate during the blade-coating process, resulting in slower heterogeneous nucleation. This contributes to the preparation of large-grain, high-quality FAPbI3 films. However, the slow drying of liquid films caused by DMF solvent leads to poor uniformity and coverage of final perovskite films. Additionally, it is difficult to thin blade-coated perovskite films for suitable thickness, which adversely affects nucleation and crystallization of the perovskite films as well as subsequent carrier transport in the devices. To address these issues, the researchers developed a meniscus-modulated blade-coating technique. Unlike traditional blade-coating methods, this technique utilizes high-speed airflow to modulate the meniscus in the blade-coating process, effectively reducing the amount of solution dragged out from the meniscus due to viscous forces and Marangoni flow, thereby achieving the thinning of the liquid film and the final perovskite film. This allows for relatively higher concentration of the perovskite precursor solution based on the DMF system. This meniscus-modulated blade-coating technique, combined with high-concentration precursor solutions, facilitates the growth of black-phase FAPbI3 films with large grain sizes, high crystal orientation and good uniformity.

This study entitled "Meniscus-modulated blade coating enables high-quality a-phase formamidinium lead triiodide crystals and efficient perovskite minimodules" was published on Joule.

This work was supported by the Ministry of Science and Technology of China, Natural Science Foundation of China, Beijing Natural Science Foundation and CAS-CSIRO Joint Project.

Figure 1. Crystallization quality and photovoltaic properties of blade-coated perovskite films based on different solvents.

Figure 2. Comparison of traditional and meniscus-modulated blade coating.

Figure 3. Properties of FAPbI3 films derived from precursor solutions with varying concentrations.

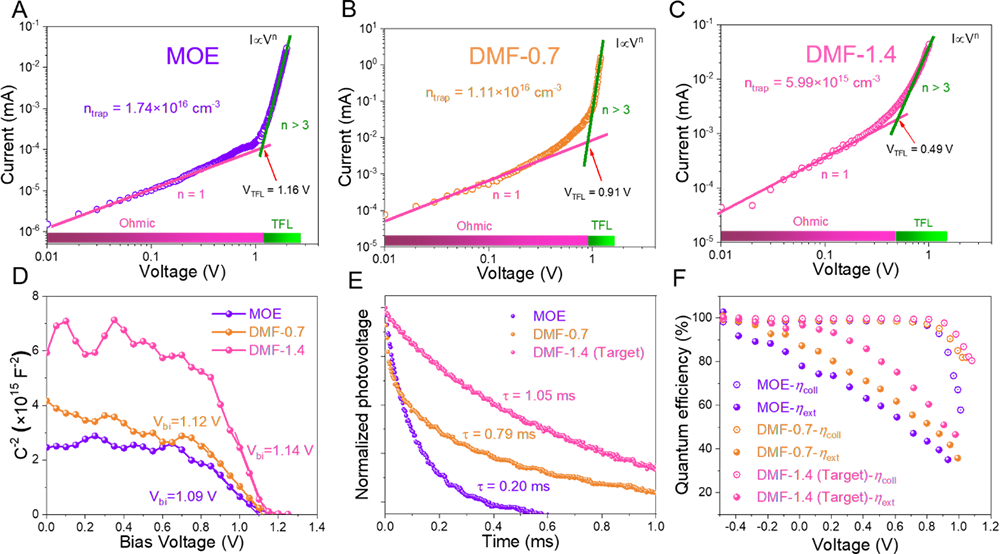

Figure 4. Analysis of defects and charge transport properties.

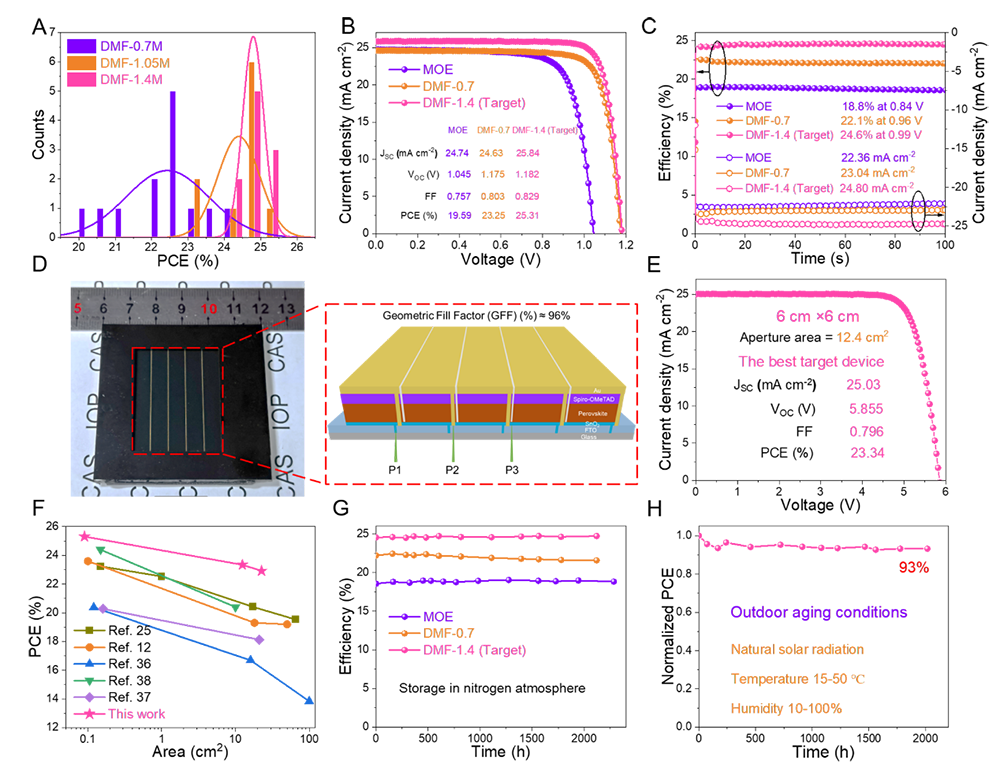

Figure 5. Performance of perovskite solar cells and minimodules.

Contact:

Institute of Physics

Meng Qingbo

Email: qbmeng@iphy.ac.cn

Key Words:

FAPbI3, perovskite solar cells, meniscus-modulated blade coating, nucleation and crystallization, modules, high efficiency

Abstract:

Meniscus coating technique is extensively employed for fabricating large-area perovskite films. Based on this technique, there are still challenges of FAPbI3 nucleation and crystallization in the film-forming process, which significantly hinders the device performance of PSC modules. Here, we developed a kind of meniscus-modulated blade coating method combined with solvent engineering to realize scalable, high-quality α-FAPbI3 films with larger grain sizes, preferred crystal orientation, excellent uniformity and controllable thickness. On this basis, a notable 25.31% power conversion efficiency (PCE) for small-size cells (0.09 cm2) and 23.34% PCE for minimodules (aperture area: 12.4 cm2) with a certified PCE of 23.09%, have been achieved. Besides, this minimodule exhibited exceptional device stabilities by remaining above 93% of the initial value after 2000h outdoor aging testing. This work provides a very promising Meniscus coating fabrication method to realize high-performance FAPbI3 perovskite solar cells and photovoltaic modules.