An integrated configuration for durable and flexible zinc ion batteries

Date:23-12-2020 Print

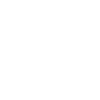

Generally, the traditional configuration of electrochemical energy storage devices is constructed by sandwiching the separator between the cathode and anode, that is, the separator is simply located between the two electrodes without enough interface interaction. When the device is in bending states, its traditional configuration is prone to suffering from the relative displacement or detachment between the neighboring components, which inevitably leads to the sharp increase of contact resistance, electron/ion transmission retardation, and deterioration of electrochemical performances. Therefore, the traditional configuration has great limitations in expanding the device to high flexibility.

The integrated configuration refers to the integration of the main components (cathode, anode, separator and current collectors) of energy storage devices into a whole, where the adjacent components can realize continuous seamless connection to ensure the stable transmission of ions and electrons even in bending states. Thus, the design of integrated configuration becomes a key to solve the problem of flexibility limitation brought by traditional separated configuration. It is a challenging task but of great significance to design reasonably and pertinently the integrated structure according to different energy storage systems. Based on their previous work on the integrated structures designed for energy storage devices (Adv. Funct. Mater. 26: 8178-8184, 2016; Chinese Patent: 2013101370105 and 2013101680826), recently, Dr. Penghui Chen, Prof. Weiya Zhou and Prof. Sishen Xie et al., at the Institute of Physics, Chinese Academy of Sciences, have developed an ingenious integrated configuration for high-safety aqueous zinc ion battery (ZIB), in which the various components have been integrated into a whole to fabricate a ZIB with high flexibility and long-life (Fig. 1).

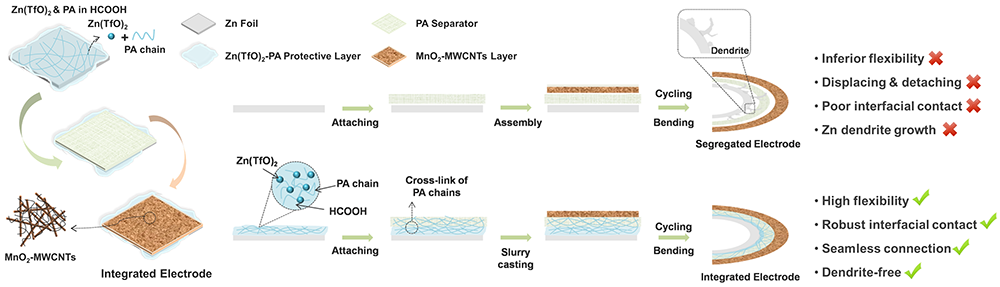

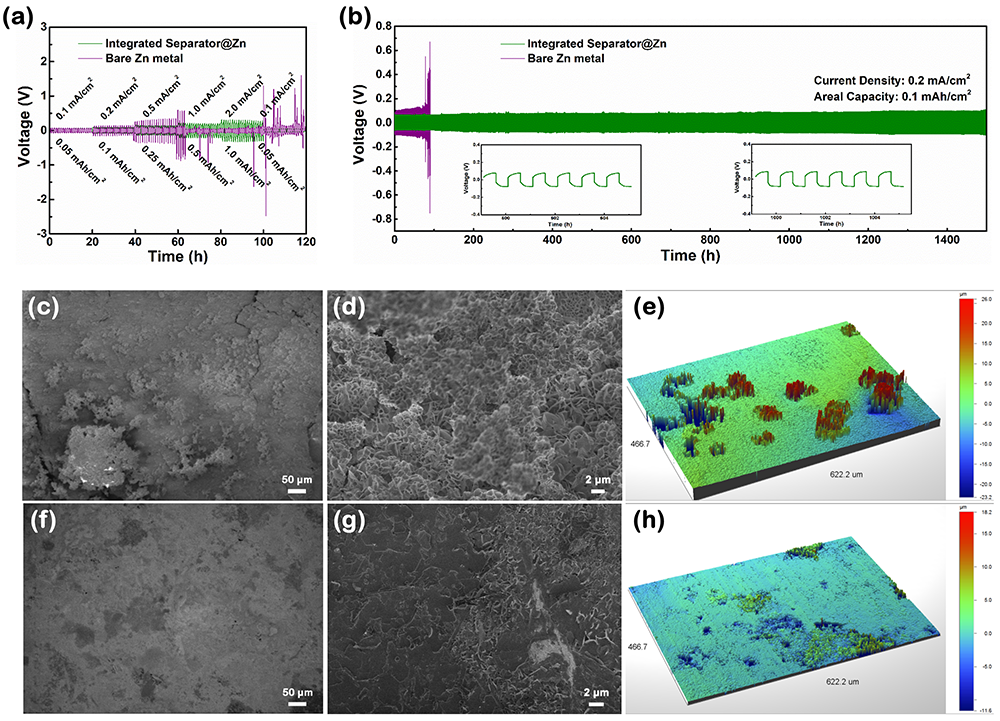

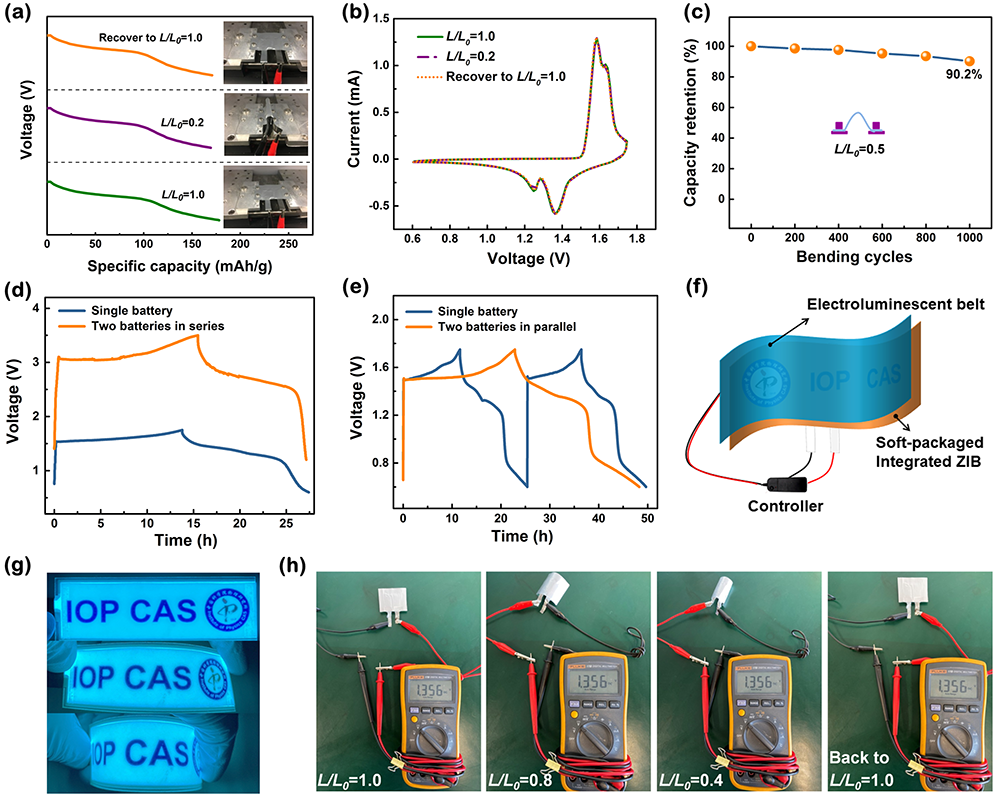

In the design of integrated ZIB, a polyamide microporous film as the separator is integrated with zinc anode through a coating composed of zinc trifluoromethanesulfonate and polyamide. The coating can play multiple roles: the binder that glues the zinc anode and polyamide film, and the protective layer to inhibit the dendrite growth and side effects of zinc anode (Fig. 2). The cathode is composed of α-MnO2 nanowires and multi-walled carbon nanotubes. The whole cathode layer acts as a collector, which saves the extra inactive components. This design can make the device thinner and improve the mass/volume energy density. In the optimized integrated configuration, the robust interaction between adjacent component layers can ensure a stable interface contact and form a seamless connection. Thus the relative displacement or separation in bending states can be avoided. Therefore, the integrated configuration has an improved rate performance, cycle stability (the capacity retention rate reaches 89.4% after 5000 cycles) (Fig. 3) as well as the flexibility (capacity retention > 90% after 1000 bends) (Fig. 4). The method adopted in this study has high compatibility with the existing battery manufacturing technology. This design ensures the inherent advantages of high safety and high ionic conductivity of aqueous ZIB, and solves the scientific problems of dendrite growth and bending limitation.

The related work entitled “An integrated configuration with robust interactive contact for durable and flexible zinc ion batteries” has been published on Nano Energy (https://www.sciencedirect.com/science/article/pii/S2211285520304626).

The work was supported by the National Key R&D Program of China (Grant No. 2018YFA0208402), the National Natural Science Foundation of China (11634014, 51172271 and 51372269), the “Strategic Priority Research Program” of the Chinese Academy of Sciences (XDA09040202).

Nano Energy 74, 104905, 2020

Fig. 1 Comparison of the construction illustration between the integrated configuration and traditional separated configuration of the ZIB

Fig. 2 Inhibition of dendrite growth and side effects on the zinc anode by integrated configuration

Fig. 3 Comparison of electrochemical performances between the integrated configuration and traditional separated configuration in coin-cell typed ZIBs

Fig. 4 Electrochemical performances and demonstration of the ZIB with integrated configuration