Anion Regulation for Pressure-Free Operation of All-Solid-State Batteries

Date:10-10-2025 Print

Researchers from the Chinese Academy of Sciences (CAS) and collaborating institutions have developed a groundbreaking strategy to overcome a major bottleneck in all-solid-state lithium metal batteries (ASSLMBs). Their work, published in Nature Sustainability, introduces a dynamically adaptive interphase (DAI) that enables stable battery operation under little or even zero external pressure—a critical step toward practical high-energy-density batteries.

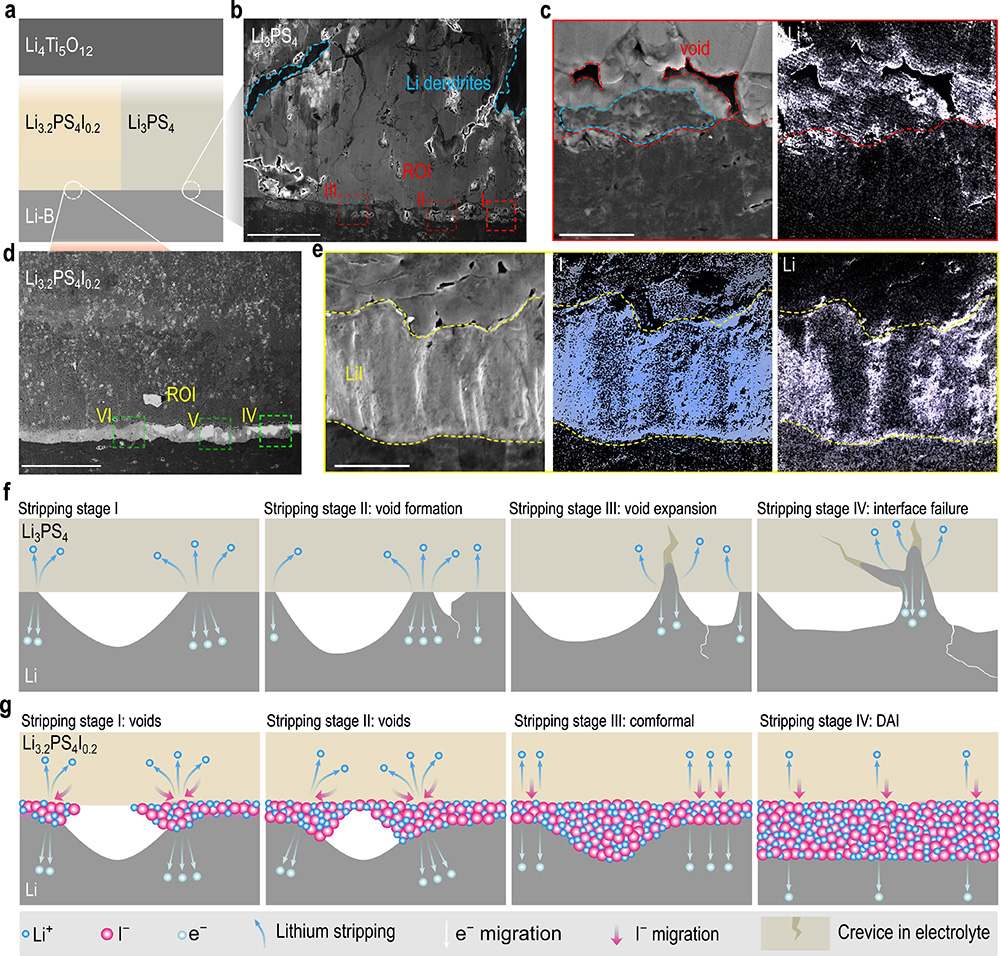

Unlike conventional lithium-ion batteries, ASSLMBs use solid electrolytes, offering superior safety and energy density. However, the rigid solid-solid contact between the lithium metal anode and electrolyte often leads to void formation, contact loss, and failure, especially under low pressure. Current solutions require impractical stack pressures above 5 MPa, hindering commercial adoption.

The breakthrough was achieved through a collaboration between research teams led by Prof. Xuejie Huang (Institute of Physics, CAS), Prof. Xiayin Yao (Ningbo Institute of Materials Technology and Engineering, CAS), and Prof. Heng Zhang (Huazhong University of Science and Technology). They proposed a novel solution: pre-install mobile anions (iodide, I⁻) into the solid electrolyte, allowing them to migrate during operation and form a dynamic, self-healing interface at the anode. "Current all-solid-state batteries require enormous external pressure—like a device that only works if you keep pressing on it," Prof. Huang explained. "Our technology acts like an automatic regulator, eliminating the need for voluminous external compression systems."

Using a LiI-doped sulfide electrolyte (Li3.2PS4I0.2), the researchers demonstrated that iodide ions can migrate to the interface during cycling, forming a LiI layer that fills voids and ensures continuous ion transport. The DAI mechanism effectively eliminates dendrite growth and interfacial degradation. The results are impressive and a lab-scale cell retained 90.7% capacity after 2,400 cycles at high current density. More importantly, for the first time, a pouch cell—a format closer to commercial batteries—achieved stable cycling for 300 cycles with zero external pressure, retaining 74.4% capacity.

Commenting on this study, Prof. Chunsheng Wang, a renowned expert in battery technologies from the University of Maryland noted, “This work resolves the notorious contact-loss problem without complex external mechanical systems. The DAI concept represents a paradigm shift in interfacial design and opens a new pathway toward sustainable, high-energy, and truly practical solid-state batteries.”

The DAI strategy is not limited to iodide; it can be extended to other anions like bromide or chloride, and may also benefit other alkali metal batteries, such as sodium or potassium.

The research article titled "Adaptive interphase enabled pressure-free all-solid-state lithium metal batteries" was published in Nature Sustainability (DOI: 10.1038/s41893-025-01649-y) and has been selected as an Editor’s Suggestion. Postdoctoral Researcher Guanjun Cen and Senior Engineer Hailong Yu from the Institute of Physics (Chinese Academy of Sciences) are co-first authors, with computational work completed by Prof. Ruijuan Xiao, and Prof. Xuejie Huang serving as the corresponding author. The study was supported by the National Key R&D Program of China, the National Natural Science Foundation of China, and the Youth Innovation Promotion Association of CAS.

Paper Link: [https://www.nature.com/articles/s41893-025-01649-y]

Fig.1 Mechanistic understanding on DAI-stabilized ASSLMBs. (Image by Institute of Physics)

Contact:

Institute of Physics

Prof. Xuejie Huang

Email:xjhuang@iphy.ac.cn

Key words:

All-solid-state battery; Lithium metal anode; Dynamically adaptive interphase; Zero external pressure;

Abstract:

Adaptive anion-derived interphases enable pressure-free all-solid-state lithium metal batteries with sulfide solid eletrolyte. This innovation achieves exceptional cycling stability over 2400 cycles with 90.7% capacity retention, paving the way for practical high-energy-density batteries.